Product

Introduction

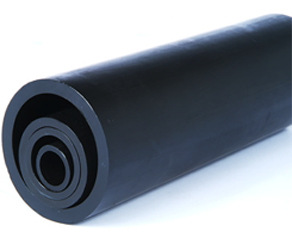

PE100 Water pipe

DAELIM PE100 water pipes are produced with the latest Krauss Maffei equipment from Germany. The water pipes, produced with cutting-edge equipment, are manufactured with improved technologies.

Basic features of DAELIM Water Pipe

Basic properties of DAELIM Water Pipe

DAELIM Water Pipe does not have electrolytic or other types of corrosion, or scale, and it is an epoch-making piping material that is nontoxic, odorless, and allows sanitary water supplies. It has especially excellent durability in electrolytic corrosion areas and coastal areas, and outstanding acid resistance and alkali resistance, making it ideal as a piping material for industrial use water.

| PROPERTIES | UNITS | TYPICAL VALUE |

|---|---|---|

| Density | g/㎤ | 0.953 |

| Melting index | g/10min | 0.1 |

| Yield tension intensity | kg/㎠ | 200 |

| Elongation | % | 600 |

| Impact resistance | kgfcm/㎠ | 13 |

| Specific heat | kcaℓ/kg℃ | 0.55 |

| Heat conductivity | w/cm℃ | 0.4 |

| Softening temperature | ℃ | 121 |

| Melting point | ℃ | 128 |

| Low temperature brittleness temperature | ℃ | ≤-40 |

| Poisson’s ratio | - | 0.4 |

| Absorption rate | % | 0.008 |

| Voltage resistance | KV/㎜ | 48 |

| Linear expansion coefficient | cm/cm℃ | 11x10-5 |

| Melting point | Water mains, water pipes, etc. |

Dimensions of DAELIM Water Pipe

Polyethylene Waterworks Pipes KS M 3408-2

| Nominal dimensions | Outer diameter (mm) |

Length (m) |

Pipe heat | |||||

|---|---|---|---|---|---|---|---|---|

| SDR 11 | SDR 13.6 | |||||||

| Nominal pressure (1 bar=1 kgf/㎠) | ||||||||

| PN 16 (bar) |

PN 12.5 (bar) |

|||||||

| Minimum | Maximum | Straight pipe | ROLL | Tube wall thickness (mm) | Tube wall thickness (mm) | |||

| Minimum | Maximum | Minimum | Maximum | |||||

| 20 | 20.0 | 20.3 | 6/9 | 120.0 | 2.0 | 2.3 | - | - |

| 25 | 25.0 | 25.3 | 6/9 | 120.0 | 2.3 | 2.7 | 2.0 | 2.3 |

| 32 | 32.0 | 32.3 | 6/9 | 90.0 | 3.0 | 3.4 | 2.4 | 2.8 |

| 40 | 40.0 | 40.4 | 6/9 | 90.0 | 3.7 | 4.2 | 3.0 | 3.5 |

| 50 | 50.0 | 50.4 | 6/9 | 60.0 | 4.6 | 5.2 | 3.7 | 4.2 |

| 63 | 63.0 | 75.0 | 6/9 | 40.0 | 5.8 | 6.5 | 4.7 | 5.3 |

| 75 | 75.0 | 75.5 | 6/9 | 40.0 | 6.8 | 7.6 | 5.6 | 6.3 |

| 90 | 90.0 | 90.6 | 6/9 | 40.0 | 8.2 | 9.2 | 6.7 | 7.5 |

| 110 | 110.0 | 110.7 | 6/9 | - | 10.1 | 11.1 | 8.1 | 9.1 |

| 125 | 125.0 | 125.8 | 6/9 | - | 11.4 | 12.7 | 9.2 | 10.3 |

| 140 | 140.0 | 140.9 | 6/9 | - | 12.7 | 14.1 | 10.3 | 11.5 |

| 160 | 160.0 | 161.0 | 6/9 | - | 14.6 | 16.2 | 11.8 | 13.1 |

| 180 | 180.0 | 181.1 | 6/9 | - | 16.4 | 18.2 | 13.3 | 14.8 |

| 200 | 200.0 | 201.2 | 6/9 | - | 18.2 | 20.2 | 14.7 | 16.3 |

| 225 | 225.0 | 226.4 | 6/9 | - | 20.5 | 22.7 | 16.6 | 18.4 |

| 250 | 250.0 | 251.5 | 6/9 | - | 22.7 | 25.1 | 18.4 | 20.4 |

| 280 | 280.0 | 281.7 | 6/9 | - | 25.4 | 28.1 | 20.6 | 22.8 |

| 315 | 315.0 | 316.9 | 6/9 | - | 28.6 | 31.6 | 23.2 | 25.7 |

| 355 | 355.0 | 357.2 | 6/9 | - | 32.2 | 35.6 | 26.1 | 28.9 |

| 400 | 400.0 | 402.4 | 6/9 | - | 36.3 | 40.1 | 29.4 | 32.5 |

| 450 | 450.0 | 452.7 | 6/9 | - | 40.9 | 45.1 | 33.1 | 36.6 |

| 500 | 500.0 | 503.0 | 6/9 | - | 45.4 | 50.1 | 36.8 | 40.6 |

| 560 | 560.0 | 563.4 | 6/9 | - | 50.8 | 56.0 | 41.2 | 45.5 |

| 630 | 630.0 | 633.8 | 6/9 | - | 57.2 | 63.1 | 46.3 | 51.1 |

| Nominal dimensions | Pipe heat | |||||

|---|---|---|---|---|---|---|

| SDR 17 | SDR 21 | SDR 26 | ||||

| Nominal pressure (1 bar=1 kgf/㎠) | ||||||

| PN 10 (bar) |

PN 8 (bar) |

PN 6 (bar) |

||||

| Tube wall thickness (mm) | PNTube wall thickness (mm) | Tube wall thickness (mm) | ||||

| Minimum | Maximum | Minimum | Maximum | Minimum | Maximum | |

| 20 | - | - | - | - | - | - |

| 25 | - | - | - | - | - | - |

| 32 | 2.0 | 2.0 | - | - | - | - |

| 40 | 2.4 | 2.4 | 2.0 | 2.3 | - | - |

| 50 | 3.0 | 3.0 | 2.4 | 2.8 | 2.0 | 2.3 |

| 63 | 3.8 | 3.8 | 3.0 | 3.4 | 2.5 | 2.9 |

| 75 | 4.5 | 4.5 | 3.6 | 4.1 | 2.9 | 3.3 |

| 90 | 5.4 | 5.4 | 4.3 | 4.9 | 3.5 | 4.0 |

| 110 | 6.6 | 6.6 | 5.3 | 6.0 | 4.2 | 4.8 |

| 125 | 7.4 | 7.4 | 6.0 | 6.7 | 4.8 | 5.4 |

| 140 | 8.3 | 8.3 | 6.7 | 7.5 | 5.4 | 6.1 |

| 160 | 9.5 | 9.5 | 7.7 | 8.6 | 6.2 | 7.0 |

| 180 | 10.7 | 10.7 | 8.6 | 9.6 | 6.9 | 7.7 |

| 200 | 11.9 | 11.9 | 9.6 | 10.7 | 7.7 | 8.6 |

| 225 | 13.4 | 13.4 | 10.8 | 12.0 | 8.6 | 9.6 |

| 250 | 14.8 | 14.8 | 11.9 | 13.2 | 9.6 | 10.7 |

| 280 | 16.6 | 16.6 | 13.4 | 14.9 | 10.7 | 11.9 |

| 315 | 18.7 | 18.7 | 15.0 | 16.6 | 12.1 | 13.5 |

| 355 | 21.1 | 21.1 | 16.9 | 18.7 | 13.6 | 15.1 |

| 400 | 23.7 | 23.7 | 19.1 | 21.2 | 15.3 | 17.0 |

| 450 | 26.7 | 26.7 | 21.5 | 23.8 | 17.2 | 19.1 |

| 500 | 29.7 | 29.7 | 23.9 | 26.4 | 19.1 | 21.2 |

| 560 | 33.2 | 33.2 | 26.7 | 29.5 | 21.4 | 23.7 |

| 630 | 37.4 | 37.4 | 30.0 | 33.1 | 24.1 | 26.7 |